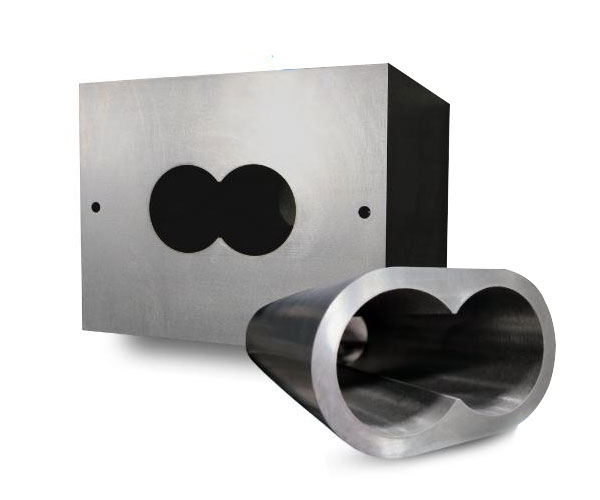

X-900™ Extreme Wear Technology

X-900? is a revolutionary bimetallic liner for co-rotating segmented twin barrels used in high-wear or high-pressure applications in resin compounding. X-900? provides an impenetrable, seamless barrier through a patented technology whereby a tungsten-carbide/nickel compound is laser-welded directly to the inner surface of the barrel segment. Our X-900? technology provides the strength, wear and corrosion protection of a bimetallic inlay with the seamless finish of brazed compounds at the apex. Unlike other technologies, X-900? segments can be relined, reducing the lifecycle cost of a segmented twin barrel.

Longer wear life (1.5-2.0x) over competition

Seamless apex

HRC 60-66

Lower lifecycle cost by relining worn X-900? barrels

Ability to eliminate the need/cost of liner sleeve

Twin segments up to 610mm (24?) in length

Bore diameter from 70-133mm

Cladding thickness 1.0-2.0mm

Retrofit nearly any worn segment with X-900?

cladded insert

Liner, block, and flange part types (with and

without cooling channels)